armorseal tread plex dry time

650SLRC 100 Solids Epoxy. Drying time is temperature humidity and fi lm thickness dependent.

Ive used treadplex before when I wasnt able to profile.

. Not recommended Clean Up. But in conversations with both my rep and corporate 2 coats of top coat treplex will give you the same adherence properties as tredplex primer and tredplex top coat. None required Shelf Life.

Sherwin-Williams Armorseal Tread Plex Water Based Acrylic Floor Coating White-Old Product. 50F10C 77F25C 120F49C 50 RH To touch. 24 months unopened Store indoors at 40F to 100F.

Products which contain chemicals that can be easily separated during normal use. 48 hours Drying time is temperature humidity and film thickness dependent. 18 hours 8 hours 6 hours Heavy traffi c.

Drying Schedule 40 mils wet 100 microns. 2 Mar 2 2013. If maximum recoat time is exceeded abrade surface before recoating.

Drying time is temperature humidity and film thickness dependent. 200F PMCC ReducerClean Up. Brush or roll usinga soft woven.

Water PRODUCT DESCRIPTION PRODUCT CHARACTERISTICS RECOMMENDED USES PERFORMANCE CHARACTERISTICS PRODUCT INFORMATION ARMORSEAL TREAD-PLEX is a general purpose. A single-component general purpose interiorexterior 100 acrylic water-borne floor coating. 18 hours Heavy Traffic.

If that doesnt make sense to you then the product will not hold up like it can. SWEAT-IN TImE 77 F None None 15 minutes None None POT lIFE NA 6 8 hours 6 hours 30 minutes 30 minutes DRy 77 F to Touch 30 minutes 1 2 hours 45 minutes 4 6 hours. ArmorSealTREAD-PLEX PRIMER is a general purpose interiorexterior VOC compliant 100 acrylic low odor waterborne primer.

1 hour 30 minutes 10 minutes To recoat. It is designed for use in commercial industrial and residential floor applications. Ideally you need to profile the floor.

A R North America Inc. 12 months unopened Store indoors at 40F to 100F. Then a time came when I ceased to recollect anythingwhen all was one awful hideous fantastic dream.

ExpressPatch Urethane Patch Kit. 4 Aug 12 2010. My throat was dry my tongue stuck to the roof of.

FEATuRES Fast-drying. 50F10C 77F25C 120F49C 50 RH To touch. At last on Tuesday the eighth of the month of July after crawling on our hands and knees for many hours more dead than alive we reached the point of junction between the galleries.

7 days 7 days 7 days Drying time is temperature humidity and fi lm thickness dependent. This dries rapidly to a tough alkali-resistant finish which will withstand hard wear abrasion grease oils and cleaning equipment. Drying time is temperature humidity and film thickness dependent.

Bristle brush 380-570 sq. C -U I-2 3 1 4 3 -2 Clean spills and spatters immediately with soap and warm water. Ftgal 2030 mils None 4 hours 2 hours 12 hours 72 hours 12-48 hours Yes Yes 650 SURC 2 components prepackaged units Rubber squeegee and cross-roll with a Jg soft woven After 20-30 minutes spike roll.

Application of coating above maximum or below minimum recommended spreading rate may adversely aff ect coating performance. A E Hand Tools Inc. Products in this Consumer Product Information Database CPID are classified based on their composition.

30 days 30 days 30 days To Cure 7 days 7 days 7 days Foot Traffic. ARMORSEAL 8100 is the next generation in water based epoxy floor coatings. 1 hour 45 minutes 25 minutes To recoat.

3 hours 45 minutes 15 minutes Foot traffi c. This dries rapidly to a tough alkali-resistant finish which will withstand hard wear abrasion grease oils and cleaning equipment. Pharos is a tool to help scientists researchers and product innovators identify problematic chemicals and collaborate to find safer alternatives.

8 hours 6 hours 3 hours maximum. Joined Feb 21 2009. A two-component polyamine epoxy with excellent chemical and abrasion resistance that is breathable.

For use over prepared concrete and wood floors steps stairwells aisleways or previously painted floor surfaces in sound condition. ArmorseAl TreAD-PleX. Solvent-resistant core roller or a natural.

A one-component general purpose interior and exterior waterborne floor coating. ARMORSEAL TREAD-PLEX Water Based Acrylic Floor Coating Deck Gray MANUFACTURERS NAME THE SHERWIN-WILLIAMS COMPANY 101 Prospect Avenue NW. Technically speaking as per the bulletin spec sheet there is a tredplex primer to be used with the tredplex top coat.

Volume New York NY 1833-1916 January 18 1908 Image 1 brought to you by The New York Public Library Astor Lenox and Tilden Foundation and. Drying Schedule 70 mils wet 175 microns. 24 hours 18 hours 10 hours To cure.

6 - 8 hours 72F 50 RH Sweat-in-time. A one-component general purpose interior and exterior waterborne floor coating. Through a rapid drying process Armorseal Tread-Plex turns to a tough alkali-resistant finish which will withstand hard wear abrasion grease oils.

200F PMCC mixed Reducer.

Certapro Painters Of Atlanta Worked On The Georgia State Capitol Building

Armorseal Tread Plex Sherwin Williams Company Sweets

Sw Armorseal Tread Plex Review The Garage Journal

Armorseal Tread Plex Water Based Acrylic Primer Sherwin Williams

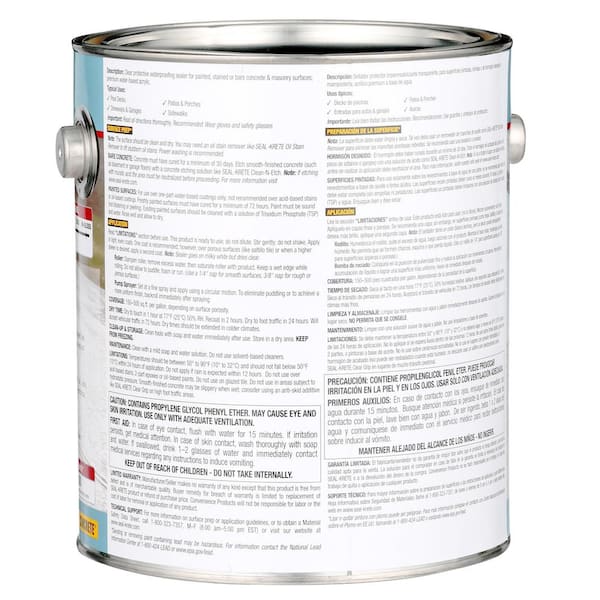

Questions And Answers For Seal Krete 1 Gal Clear Seal Low Gloss Sealer

Armorseal Floor Coatings Sherwin Williams

Sw Armorseal Tread Plex Review The Garage Journal

Commercial Performance Floor Coatings Sherwin Williams

Questions And Answers For Seal Krete 1 Gal Clear Seal Low Gloss Sealer

Armorseal Tread Plex Protective Marine Coatings

Sw Armorseal Tread Plex Review The Garage Journal

Sherwin Williams Concrete Catalog By Sherwin Williams Issuu

Painting Systems Catalog 2015 2016 By Sherwin Williams Issuu